Product Description

THE MARINE INDUSTRY’S HIGHEST RATED WIND GENERATOR

MarineKinetix MK4+Wind Generator, including Controller - For Lead Acid, AGM, Gel and Lithium Batteries.

The marine wind generator with a 100% satisfaction guarantee, and the industry's best 3-year limited warranty.

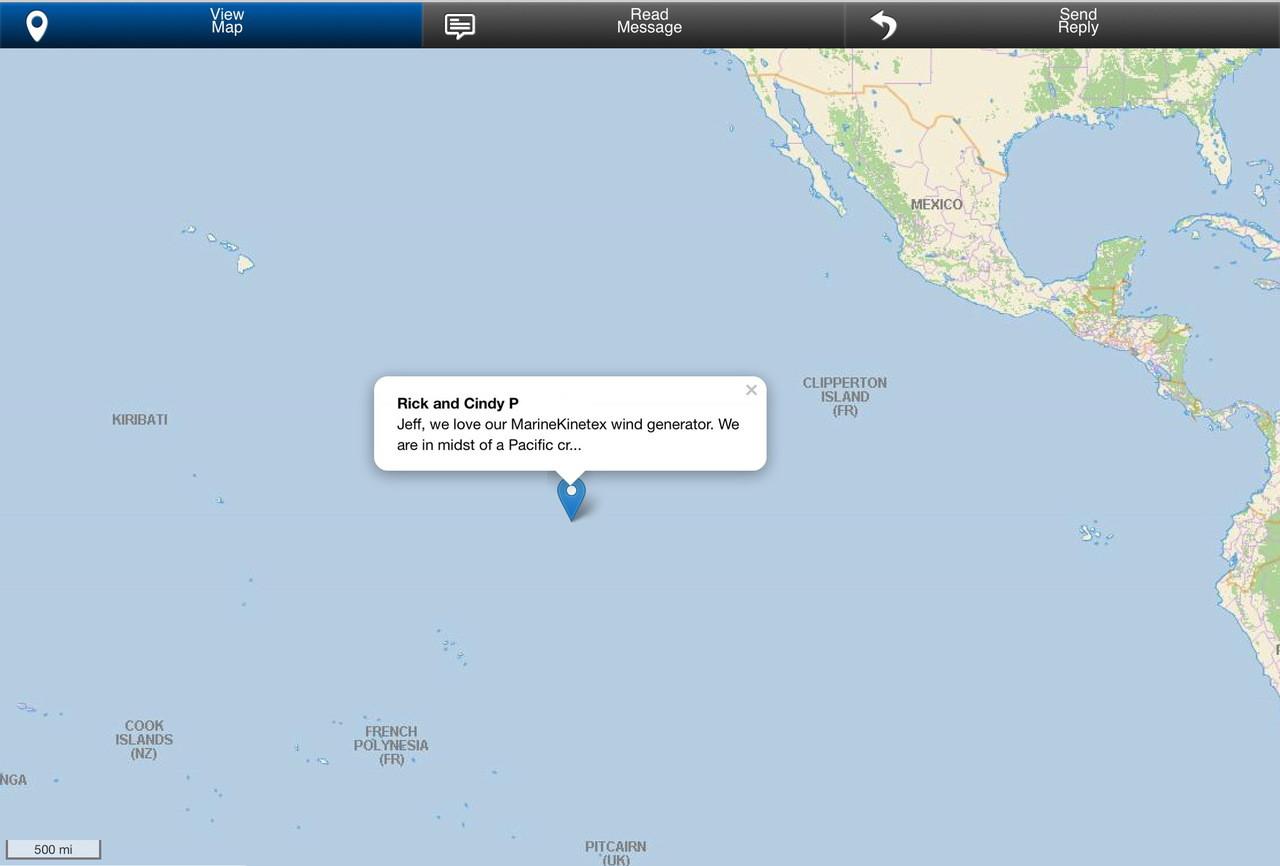

Double click on the large picture above to scroll through scores of pictures of fellow bluewater cruisers worldwide relying on power from their MarineKinetix wind generator. Also see a blog from a seasoned bluewater cruiser and Salty Dawg Rally organizer who solved his large energy demands using a combination green energy, including an MK4+ wind generator here.

The MarineKinetix Wind Turbine has become one of the most popular marine wind generators available due to its advanced technology, superior output, and super-quiet design. The MarineKinetix is now considered to be the benchmark among serious cruisers. With a 30% to 50% larger swept area than the most popular marine wind generators, it is simply capable of intercepting more of the available windstream, and capturing more power. Its sophisticated microprocessor-controlled charge controller displays all the data, including wind Amps, Watts and Volts, and assures that the power makes it safely and efficiently into your battery bank through a 2-stage smart charging process. No need to buy extra meters, rectifiers, stop switches, or load diverters. These are integrated into our smart controller. Just add your mounting pole and the wiring to your batteries, and you are ready to start producing green energy.

We are celebrating our 12th year of serial production, and our 8th year producing our latest design, the MK4+ Marine Wind Generator. The MK4+ replaced the popular MarineKinetix MK450. Our wind generators are in use from the southern ocean to the arctic ice shelf.

The MK4+ includes the following upgrades:

- The Wind Generator body is smaller and even lighter than the original design. This is accomplished with a shorter, but more upright tail, with a greater surface area, and lower polar moment, for faster, and truer wind-tracking. This lowers yaw error and improves performance in shifting winds.

- Upgraded asymmetrical pole-shifted rotor with 12 (vs 10) neodymium rare-earth magnets for more power and zero cogging. Bread-loaf magnet design for optimum air gap.

- Upgraded 36-slot stator with premium heavy-gauge copper windings.

- A new and improved anti-corrosion marine grade finish, which starts with a new high-pressure die-cast magnalium body, which is GEOMET zinc-nanocoat pre-treated, then top-coated with a high-quality corrosion-resistant thermoset marine powder coating. No other marine wind generator uses this anti-corrosion process

- New double yaw bearings. Double bearings provide a larger "wheelbase" for the yaw joint, which reduces any free play, which can contribute to vibration and noise.

- Improved silicone o-rings which are totally weather-proof.

- Improved Aero'coustic 20% carbon-fiber filled injection molded blades, which are 18% more rigid than the previous design.

- All new Hybrid Wind/Solar Charge Controller with LCD display - with integrated battery monitor, stop switch, ammeter and watt meter. (no need for expensive monitoring panels).

- Patented 2-Stage PWM Charge Controller - Increases the efficiency of the charge cycle and tops up the batteries quicker and more fully.

- Improved high-precision hub, with tighter blade fastening tolerances, for perfect blade alignment and whisper-quiet operation.

- Improved molded urethane isolator pad, which fits between the pole and the collar. Molded in "cap" allows it to stay put during assembly.

The great performance of the original MK450 remains. The above changes are incremental improvements designed to improve start-up speed, ease assembly, resist corrosion, and improve real-world output. The MK4+ is truly a world-class micro wind generator.

Tired of talking to non-technical vendors that don't understand the nuts-and-bolts of what they are selling? Give our technical rep, Jeff, a call directly at (864) 275-7837 to answer any questions. Read on to see what really matters when considering wind power for your boat.

Why Consider the MarineKinetix Wind System?

The MarineKinetix Wind Turbine System is simply one of the best performing small wind generator system available for marine use. That is quite a boast, considering all the small turbines out there with catchy names, and bigger advertising budgets, but read on to find out why we believe you'll soon agree.

The MarineKinetix MK4+ is a simple to install, hands-off, super-quiet wind-energy production system made especially for the marine environment. This high-output, low start-up-speed system utilizes the best of European wind-science in its design. In addition to its leading-edge high-output dual-bearing 3-phase permanent magnet generator, it also features world-class aerodynamic efficiency with its carbon-filled aero'coustic rotor blades, which have been optimized for high torque, low rotational inertia, and exceptionally quiet output. These features, coupled with the included "hands-off" microprocessor-based charge-controller, and its exceptionally low yaw-error, make for what we think is the best marine wind generator system on the market. See why below.

The MarineKinetix MK4+ wind turbine system is a leap forward in wind turbine science. It makes the intelligent compromise between low-speed start-up and high-speed output, all at a realistic and cost-effective price.

- A complete 400 Watt Wind System (includes generator and controller)

- 1330mm Blade Diameter (1.3M) - Swept Area = 1.39 Meter

- Weighs only 17 lbs., about HALF the weight of certain competitive designs, without compromising performance thanks to a magnalium body, an asymmetrical rotor, and high-energy-density Nd2Fe14B rare-earth magnets

- Lightweight 300g 20% Carbon Fiber Polymer Composite blades

- Available in 12V, 24V and 48V designs

- Compatible with VRLA, Gel, AGM, Lithium, and Lithium Iron Phosphate (LiFePO4)

- Industry Standard Mounting - Mounts to 1.5" Schedule 40 pipe (1,9"OD), or 48-50mm OD tubing

- Double marine thermoset powder-coat finish, over a DACROMET self-healing aluminum-zinc nano coat

- 5.8 knot start-up speed (begins producing power), 6.7 knot cut-in speed (begins charging 12V/24V batteries)

- Aero'coustic 20% Carbon Polymer Blades

- Super-silent - LAeq 35dB at 5M at 10 knots (about the same as a running fridge)

- Direct drive, 3-Phase dual-bearing AC permanent magnet synchronous generator

- Neodymium Iron Boron (Nd2Fe14B) permanent magnet synchronous design

- 12 pole rotor, with bread-loaf magnet profile, and asymmetrical pole-shifted magnet placement, for low cogging torque

- Automatic back-EMF braking at full charge (or 40 knots overspeed protection)

- IU PWM Charge Control Profile with hysteresis braking

- Microprocessor controlled auto set-point for AGM, Gel, VRLA, Flooded, Lithium, and Lithium Iron Phosphate (LiFePO4)

- Requires no diode packs, diverters or external resistive loads

- Over-charge, over-current, and automatic over-speed protection

- Integrated heavy-duty yaw-axis slip-ring, allowing continued >360° limitless rotation

- Simple installation, and user-serviceable components

- Includes micro-processor charge controller with "at-a-glance" LCD charge, voltage, amperage and wattage status

- Fully compatible with existing solar installations (no conflict with other existing charging sources)

- 3-year limited warranty, and 30-day 100% satisfaction guarantee

- Full lifetime tech support by phone or email with purchase

What is included in the Wind Generator kit?

- MK4+ Wind Generator

- Smart Charge Controller with integrated performance monitor and stop switch

- Blades (x3) with SS blade mounting hardware

- Hub, with mounting nut

- Snap-on molded plastic nose cone

- SS Hardware to mount clamping collar to your pole

- Silicone rubber isolator (goes between pole and mounting collar)

- Assembly allen key tools

- Instructions

What installation accessories and spare parts are in-stock and available from Marinebeam?

- 50A Resettable Circuit Breaker

- Pole Mounting Hardware Kit

- 3-Piece Pole Mast

- 10/3 Marine Cable

- Spare Parts

What is the wired Remote Stop Switch Connector option?

While the controller already has an integrated stop switch --accessed with the front panel buttons-- some customers who will have limited access to the controller location may wish to mount a secondary stop switch in a more accesible locaton. So, this option includes a two-pin connector, which attaches to a port on the bottom of the controller, and allows you to run your small-gauge wiring to your on/off toggle switch. The switch and extra wiring are not included, but this is a very low voltage and low current control signal, so a light gauge wire (18-22 AWG) is sufficient. For more sophisticated systems (like off-site telemetry systems) a relay can be used to remotely actuate the brake.

Details About the Unique Marine Kinetix Technology:

Our solution is a systems-approach to wind-energy production on-board. The MK4+ system couples several forward-thinking ideas into one "wind-system" which is easy to install, affordable, and maximizes energy production. We did this by first starting with a low-friction, high-energy-density 3-phase rare-earth magnet rotor design, which came from concepts and materials used in leading-edge green-energy vehicle research. The Neodymium Iron Boron (Nd2Fe14B) permanent magnet rotor uses patented technology licensed from Sumitomo/Hitachi in Japan. This is the same type of PM rotor design used in the AC synchronous motors in the Chevy Volt and other electric vehicles. The rare-earth magnetic rotor is a key to its performance and low noise and vibration. We now utilize an asymmetrical pole-shifted rotor design, which is a advanced method that replaces the heavy mass and cost of older skewed rotor designs, while providing the same advantage of reducing the cogging torque, and improving low speed performance. We coupled this super-efficient machine with a biomimicry-inspired carbon-fiber-filled blade set, which makes for super-quiet performance while improving overall aerodynamic power.

The results are a turbine that outperforms others in start-up speed, output, and noise. While other systems are idle, the MK4+ is generating. While other systems are disturbing the peace, the MK4+ is virtually silent. While other systems are struggling to charge, the MK4+ is topping off.

What are the important factors in wind energy production?

Physics dictates the basic performance of all wind generators. In fact, the power available to any wind generator is a function of the square of the diameter (swept area of the blades) and the cube of the wind speed. The ability of any specific wind generator to the capture wind efficiently depends on the length of its blades (its swept area) and its Tip Speed Ratio. Tip Speed Ratio refers to the speed of the tips relative to the speed of the wind. If the blades spin too fast relative to the wind, they begin to begin to look like a solid disk to the wind, and air piling up in front of the blades effectively blocks the wind behind it. On the other hand, if the blades spin too slowly, much of the wind passes through the gaps between the blades, and the energy is lost forever. So, swept area and blade design are the most important areas which the wind generator manufacturer can control. While the MK4+'s blades are only 8 to 9 inches longer than the typical blade, they sweep as much as 40% more area than the competition. With a nearly perfect tip speed ratio due to the computer-modeled and simulated blade design, and the impedance load-source matching of the controller, the MK4+ has a higher energy capture compared to most other designs.

Because of the cube relationship of wind speed to power production, wind speed is absolutely the most important factor in wind energy. There is no getting around the physics of that. There is 27 times more power in a 15 knot wind than a 5 knot wind. The key takeaway here is that regardless of the technology, you need good wind to get good performance from a wind generator.

What affects the ability to maximize output power capture shown above?

Wind generator power is dependent on wind speed, battery acceptance rate, and applied load, so a variable load and a discharged battery was used to characterize the absolute capture power for the data above. As the wind increases, your wind generator will already be charging full-time, and the battery bank's acceptance-rate, in amps, will decrease as the battery charges and its voltage increases. So, it is important to understand that by the time the wind is blowing 20 knots or more it is likely your batteries will not be capable of accepting the full amount of amps that any generator can provide. This is good. It means that your batteries are reaching a full state-of-charge, and that you have the headroom in power to cover any other loads as they arrive, without further discharging your batteries. At the end of the day, it is best to think of a wind generator as a free-energy variable power source, whose output changes day-to-day depending on the available wind and the presence (or absence) of downstream electrical loads that it requires to generate power.

Read the following pages to learn about the MK4+, and view the video below to see how it performs against a much more expensive wind generator at very low wind speeds.

Our Integrated "Wind-System":

Many popular marine wind generators are essentially sold in kit form, with the user left to decide what method of control they need to get the power into their batteries effectively. Alternatively, some turbines have an included charging set-up, but offer what is essentially a simple automotive voltage regulator and a load diverter. This can be a real problem for those wanting to optimize charging and protect their expensive batteries. It is not enough to just generate efficient and effective power at the generator head. It is just as important to get that power effectively into our battery bank, and to regulate that power based on the battery's specific demands for voltage and current throughout its charging cycle. By use of an IU charging profile, the system not only can be more efficient, but can also significantly prolong the life of the batteries by preventing overcharging. Typical load diverter type controllers can only charge your battery to about 80% State-of-Charge (SOC). This partial cycling is particularly bad for your batteries.

Combining the Low Start-Up Speed "Tortoise Approach" with the High-Power "Hare Approach":

Having seen both real-world performance in various anchorages around the world, as well as published performance testing over the years, we realized that the best approach out there on the "real water" was to apply leading-edge technology to each component of the system to find an intelligent compromise between the Tortoise Approach and the Hare Approach to wind energy production.

A small wind-system that is capable of making power in low wind speeds can take advantage of a long day with low wind speeds by putting small amounts of power into the battery consistently throughout the day and night (the Tortoise Approach). On the other hand, a larger system can take advantage of big gusts or heavy wind by making tons of power very quickly (the Hare Approach). The perfect solution for us cruisers would be a two-stage turbine that could be the Tortoise in low wind speeds, or protected anchorages, and could be the Hare in a high-velocity wind environment.

By leveraging leading-edge technologies to make incremental efficiency improvements in each of the discrete components of the wind system, we achieved a "sum of the parts" that meets our goals for an ideal marine wind system in-board. We believe it is the best marine wind generator on the market for those sailors wanting a high-quality, hands-off, high-output, and super-quiet system. Our real world data and feedback from our customers backs up that claim. Read on to see how we did it.

The Blade Set:

We have found that the practical key to consistent production on-board is to start with a large 1.39 meter swept area, and then to apply leading-edge technology to the blade set to extract the maximum amount of energy. Swept area is the most critical aspect of energy capture, and the bigger the swept area, the more power, period. Blade length defines the swept area (Area=πr2), and typically the longer the blades, the stronger and heavier they must be to withstand the exponential increase in torque. The MK4+ solves this issue by using a unique 20% carbon fiber molded blade that is not only long and rigid, but extremely light as well (<300g). This allows us to produce a blade that is up to 9" longer than the competition, but it weighs much less, and sweeps up to 40% more area.

We also focused on the airfoils to get a super-efficient, super-quiet, Aero'coustic blade that gives exceptional power while maintaining low-speed start-up capability. This way the turbine can take advantage of all-day energy production, but also can generate more serious power when the winds pick up. It doesn't do much good to have great potential generating capacity if the blades never turn in the real world. Compare our start-up and output to the competition, and you will see the distinct advantage.

Details of the Design:

The blade and tail design focuses on several key strategies:

- Low Start-up Speeds

- Very Low Rotational Inertia

- Very Low Noise at Optimum Tip Speeds

- Very Low Yaw Error

- Optimized Tip-Speed Ratio (the ratio of the speed of the tips to the speed of the wind)

While our carbon-fiber reinforced blade set has an extremely low rotational inertia, a strong and lightweight blade is only part of the story. The starting torque on a wind turbine is generated in the blade area closest to the hub, while the power producing torque is produced in the blade area closer to the tips. By use of German-engineered computer modeling and simulation, a variable blade profile was produced that can react quickly in low wind speeds, yet produce high torque and optimal tip-speed ratios at high speeds. The blades are produced in a solid-model-patterned single-cavity injection-molding tool, so that each blade is identical in weight and profile. Using a 20% carbon-fiber filled polymer makes the blade very light, durable, and repeatable.

Lightweight blades have a low rotational inertia, which is critical in wind-energy production in the real world. Low rotational inertia allows the blades to accelerate more quickly, which means they can spin faster in lower wind speeds, therefore keeping the tip-speed-ratio (the speed of the tips vs. the speed of the wind) more constant. Operating closer to the optimum tip-speed-ratio during gusts also allows the turbine to improve energy capture from these sudden gusts as well.

Another way to increase aerodynamic efficiency --and to reduce noise on an airfoil blade-- is to manipulate and control the lateral airflow over the foil. Of course, some of the best engineering solutions often come from mimicking what is already found in nature. Whales and certain fish have amazing hydrodynamic efficiency and stealth through the use of tubercles, or raised and slotted sections on the leading edges of their fins. Our blades likewise use biomimicry-inspired riblets along the leading edge of the blades, which help the airfoil to create more power at lower speeds, and to operate more efficiently in turbulent air streams. These Aero'coustic riblets, also prevent the air from traveling down the blade edge and "vortexing" off the blade tip contributing to tip noise. The noise you hear from most wind turbines is the sound of wasted energy.

How quiet is it...really?

The MK4+ is extremely quiet, and we have never heard one quieter. In fact, it measures only 35dB at 5 meters in 10 knots of wind. At 15 knots, just a flutter, but no tip noise. As the wind builds the flutter noise will increase. Above 30 knots, everything exposed to the wind at that velocity will generate some noise, including the MK4+. To get an idea of how quiet it really is, just watch the video below. Note that the video was shot with a CMOS rolling-shutter camera, so the blades appear to be turning slowly, while in actual fact they are turning at several hundred RPM. Video compliments of customer Hayden Cochran on his Island Packet "Island Spirit":

What is Yaw Error, and why is it so important?

Yaw Error is the difference between the direction the wind turbine is facing and the actual direction of the wind itself. As this yaw error increases, power decreases geometrically. Because these geometric losses associated with yaw error are so significant, it is surprising to see some of the popular turbines designed with a downward facing tail. This is a massive mistake. Tail design, and the reduction or elimination of yaw error, is another very important element in the MK4+'s design. Our upward facing fin (not blocked by mounting pole) and large self-tracking tail is wind-tunnel designed for minimal yaw error and maximum tracking efficiency. Compare our wind-tracking to the tracking of the mass-produced units sold by the "big box" marine stores and you can easily see (and hear) the difference.

Intelligent PWM Charge Control:

One of the most important and unique elements of the MK4+ Wind System is the integrated approach to charging control. While the generator head itself makes wild 3-phase AC power to maximize efficiency, our microprocessor-based controller actively rectifies that power into DC before dosing it out to the batteries in an IU charging sequence.

This is quite different from most of the other, and more expensive, 400W generators. The typical marine wind generator charge controller uses 50 year-old technology, which is simply a load-diverter switch, which, upon reaching a set-point, diverts 100% of the energy to a set of resistive elements (essentially heater coils). So, when the battery reaches its dumpload set-point it isn't actually fully-charged, and this type of Partial State of Charge (PSOC) cycling damages the battery by reducing its capacity, and sulfating the battery plates. They can't fully-charge the battery because they have no way to dump only the excess power produced, while continuing to top up the battery. They can only dump all of it. The best scenario would be to have a way to progressively dump power so that the batteries could be fed with only the power that they need at this final stage of the charging process.

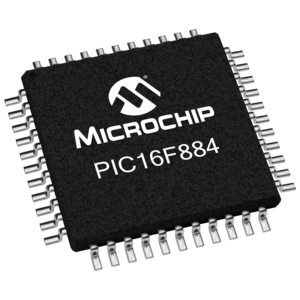

The MK4+ uses a RISC CPU 8-bit PIC microprocessor-based charge controller that works quite differently. It has three set-points. When the MK4+ Controller senses that the batteries are nearly charged, it goes into its voltage-control charge mode. In this mode, it dumps the excess power internally using a Pulse-Width-Modulation(PWM) load dumping sequence, using thousands of individual steps. At this point, it dumps only the power it doesn't need to complete the final charging stage, while the rest goes into the battery. When the controller senses that the battery is in a full state-of-charge, all of the power is diverted away from the batteries. At full charge, and high wind speeds, the controller will actuate its back-EMF brake, which will magnetically add load to the machine, slowing the blades. It cannot overcharge, and works with any lead-acid chemistry, including flooded, AGM, and Gel Cell batteries. The final set-point is a safety braking set-point, and is employed only if there is too much current being produced during charging which could damage the windings of the wind generator. The safety brake will stay employed for up to 20 minutes, and automatically release when things cool down.

using thousands of individual steps. At this point, it dumps only the power it doesn't need to complete the final charging stage, while the rest goes into the battery. When the controller senses that the battery is in a full state-of-charge, all of the power is diverted away from the batteries. At full charge, and high wind speeds, the controller will actuate its back-EMF brake, which will magnetically add load to the machine, slowing the blades. It cannot overcharge, and works with any lead-acid chemistry, including flooded, AGM, and Gel Cell batteries. The final set-point is a safety braking set-point, and is employed only if there is too much current being produced during charging which could damage the windings of the wind generator. The safety brake will stay employed for up to 20 minutes, and automatically release when things cool down.

The controller is very compact (5-5/8" H x 5-7/8" W x 3-1/4" D), fanless, and is designed to be bulkhead mounted.

It has the following additional features:

(1) Full monitoring capability (Volts, Watts, Amps), no additional battery monitors, shunts, panels, or displays needed

(2) Backlit LCD display with clear graphical readout

(3) Manual Brake deployment via keypad, so no additional stop switch is required

(4) Battery charge level indicator

(5) External load control (for managing lighting, etc)

Unlike some other popular marine wind generators which have internal controllers, there are no on-board electronics in the hot and salty elements, and there is no need for additional rectifiers, heat sinks, stop-switches, large resistive loads, or ammeters. It all happens automatically and safely within the charge controller. It even protects from over-charging and under-charging. It is truly a hands-off charging solution

Maintenance and Warranty:

The MK4+ is designed to provide years of trouble-free service out in the elements, and has a 3-year warranty against defects in materials or workmanship. We specified a simple and rugged mechanical set that uses very few parts, is easy to maintain, and will stand up to the rigors of the marine environment. Unlike most single bearing automotive alternator-based designs, our dual low-friction rotor is supported by two low-friction bearings to provide long-life and easy start-up. The unit is easy to disassemble, understand, and maintain. The body is made of a lightweight magnesium and aluminum alloy, which is pre-treated with a zinc-aluminum nano-coat, and then a double marine-grade epoxy powdercoat to resist oxidation and corrosion. See our warranty details in the manual for full terms and conditions.

The MK4+ is bluewater tested by full-time cruisers, and like all of the Marinebeam products it is backed by the best technical support and warranty in the business. Be sure to look at the various customer installation picture above to see some of our installations around the globe.

Interesting Links

Click here for our Frequently Asked Questions (FAQs) document.

Link to download PDF copy of installation manual (V2.2)

Link to download PDF copy of controller manual (V2.1)

Should you have further questions, feel free to contact us by phone or email. Jeff, our resident MK4+ technician can be reached M-F 9-6PM at (864) 275-7837. Or you can reach him by email at jeff@marinebeam.com

Product Videos

Custom Field

Product Reviews

23 Reviews Hide Reviews Show Reviews

-

Working great!

I really wanted a wind generator on our sailboat as it is a Dutch boat and it should have a windmill. I am in Europe but chose the Marinekinetix due to the reviews and the amazing support and education on generator operation and installation. We have the 24 volt for lithium and in the Northern latitudes of Norway this Summer it is really contributing to our wattage needs, along with our newly installed solar. We had an older type AirX on our farm and it was a noisy beast and the Marinekinetix is genially quiet except for the welcome sound of electrical generation. The extra attention by Marinebeam extended to excellent international shipping to get us our unit in The Netherlands. Harley SV/Prudence

-

Wind Generator

Super happy with this purchase! It is everything I hoped for. Tech support was super helpful with my install. Smooth, quiet, and powerful. This unit is a work of art!

-

wind generator

didn't know how worn out my old one was until i installed my new one.

-

Great Unit with Great Service

I had this wind generator running for the past 6 years at the top of my mizzen mast on my sailboat as good and reliable as the first day i put it up there. Sitting at the top of the mizzen mast i needed to install a unit with low maintenance as i can’t easily climb up to the top. Summer, winter this thing is running non stop for the past 6 years without a single issue and performance is very good. I use to have the Air Breeze which i don’ miss at all. If you are looking for a great unit at a great price don’t hesitate you will be very pleased with this wind generator. And as an added bonus you will get outstanding customer services.